Dave Buttress

Designer

The story of one of the most successful white metal and resin manufacturing businesses has humble beginnings.

Back in 1988, Dave Buttress was a Farm Manager working on a large farm in Newark, and as a hobby he built 1:72 scale model aircraft. Dave became the director of the Newark Aircraft Museum, and there launched a model aircraft club.

Subject ID: 82176

MoreThe story of one of the most successful white metal and resin manufacturing businesses has humble beginnings.

Back in 1988, Dave Buttress was a Farm Manager working on a large farm in Newark, and as a hobby he built 1:72 scale model aircraft. Dave became the director of the Newark Aircraft Museum, and there launched a model aircraft club.

The museum had just moved to its current site on the ex RAF base at Winthorpe near Newark, and with the club being part of the museum, it wasn’t long before the club was commissioned to build a diorama of the site for promotional purposes.

It was then that John Adams joined the club, and as he had just left the RAF, he was looking for something to occupy his time. John had a passion for model trains, and had just bought Millholme Models, a producer of high quality model railway white metal castings.

Meanwhile, Dave had mastered a resin nose cone as a conversion kit to create a Griffin Spitfire out of a standard kit. One dark rainy night at the Museum, John and Dave decided that they should begin producing conversion kits for model aeroplanes. As John’s interest was jets, he worked on creating an ejector seat out of white-metal, which had the secondary effect of making a completed plastic kit much more stable, given its three wheel undercarriage.

3 or 4 months later, 4 or 5 different conversion kits had been created. Dave was approached by Ed Deeley, of ED models in Shirley, Birmingham, who was seeking a caster to make 1:72 and 1:48 scale figurines of RAF figures from masters that he had had made. A deal was struck, involving Ed selling Dave’s white metal kits and parts, and Dave would cast the figurines.

By 1989, Dave had bought his first casting machine. At this time, Chris Arnott was running a business in Birmingham producing resin parts for a number of model vehicle and railway manufacturers, and Dave approached him for some resin casting.

Chris’s resin production was bulging at the seams, and a happy association became obvious; Chris asked Dave to join him in Birmingham, with Dave leading on white metal, and Chris on resin. Together they formed CMA Mouldcast as a partnership in 1991.

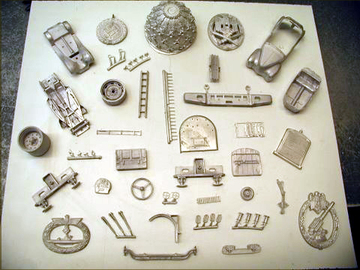

Dave’s wife Dorothy assisted Chris on the resin side of the business, and demand continued to grow with significant regular orders for ‘trade’ casting coming from as far afield as Australia and the United States. In 1992, Dave mastered some 1:43rd resin and white-metal kits of classic Riley cars, which were sold under CMA’s own name, and at around the same time Dave’s own DB range of aircraft conversions became a direct licence made product of the company. Other large contracts at that time included providing the white metal ‘super-detail’ parts for Airfix and Heller kits.

With yet more casting work coming in, they made the decision to buy another 2 casting machines, making 3 in all. The white metal side of the business was proving very profitable, with resin production running along side by side. Over the years, Dave recalls providing a casting service to many of the well-known names in the market, such as Marsh Models, Modelauto, Promod, Fire Brigade Models, Crossway Models, Ralph Horton (RSH), Pegasus and many others.

Business direction was becoming more focussed, and in 1996 the rights to the Riley kits were sold to Roger Tennyson of Crossway, for whom they have since cast many other models. Contract casting remained the core business of the company throughout, and the aircraft accessories side was sold to E.D. Models. By this time Dave’s son Kevin had joined the company to strengthen the growing production white metal and resin production teams

In parallel with the scale model manufacturing side of the business, now a Limited Company under the name CMA Moldform Limited (the omission of the ‘u’ in ‘Moldform’ was deliberate!), had expanded into resin production of prototype and industrial components, early orders including automotive dashboards and components for full-size instructional and display aircraft engines.

By 2000, Chris had become interested in exploring the potential of 3D CAD as a means of producing master patterns, this including the use of a 3D scanner to ‘capture’ the shape of an existing model to allow it to be re-scaled larger or smaller. With Dave in a position to buy out Chris’s share of the business, he left to pursue his own ideas. Yet another white metal casting machine was purchased to cope with rising demand, and contracts were successfully obtained with diverse customers such as artistic promotion companies, the RNLI for lifeboats, and White Ensign Accessories making miniature accessories for 1:200 scale ships.

More recently, CMA have completed a commission to produce a medical presentation of an encapsulated hospital bed and wheelchair in 1:20 scale, CAD design work being undertaken by Chris. Dave now has a Head of Department overseeing the white metal services, with 4 casting machines and the staff to operate them. The masters for all the contract work are now created by pattern makers selected by the client. However, masters have recently been produced for Corgi for their range of large scale figurines of popular TV programmes, and these are then produced in China.

Today, Dave feels that about 1/6th of the business is white metal, and the overall amount has reduced by some 20% since the earlier days. This is partly due to the versatility of resin, and also due to popular imperatives. Model kit producers find that the 1-piece resin body is much more popular now than flat-sided white metal kits for buses. Postage costs are much lower on resin kits too, and the detailed obtained in the moulding process can be higher.

Subject ID: 82176

Subject ID: 82176